In today’s highly competitive electronics manufacturing industry, ensuring product quality, cost-effectiveness, and operational efficiency is more crucial than ever. One of the areas often overlooked, yet incredibly vital to a robust manufacturing process, is the inspection of conformal coating—a protective layer applied to electronic assemblies to guard against moisture, dust, and other contaminants. Without proper inspection methods, these coatings can become a point of failure rather than protection.

TL;DR: Conformal coating AOI (Automated Optical Inspection) systems play an essential role in detecting defects, ensuring consistent coverage, and improving throughput in modern electronics production lines. These systems reduce human error, help maintain regulatory compliance, and ultimately decrease reject rates and costly rework. For companies striving to deliver high-reliability products, investing in AOI for conformal coating is indispensable.

What Is Conformal Coating, and Why Does It Matter?

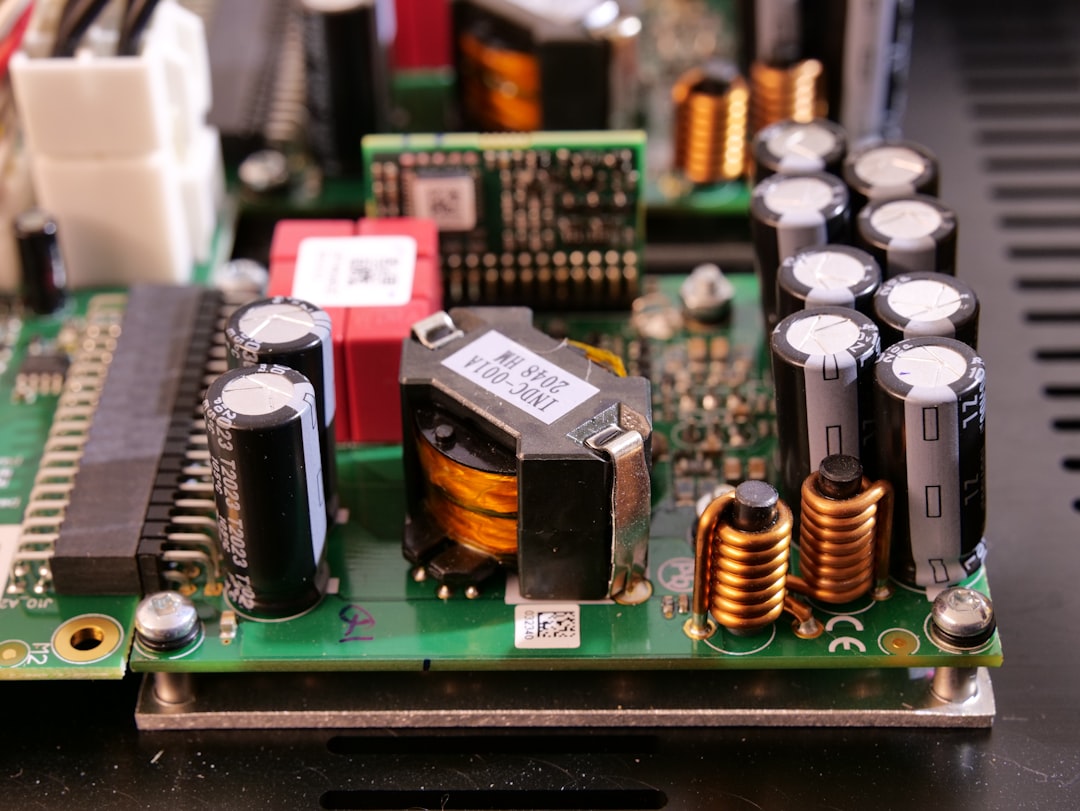

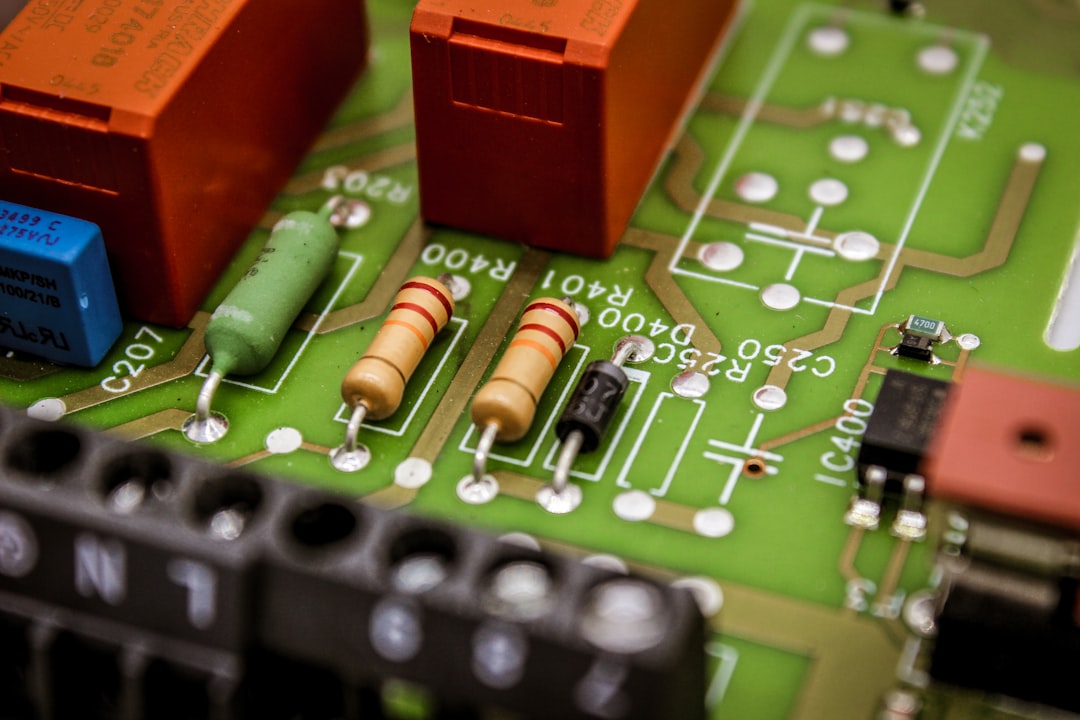

Conformal coating is a thin polymeric film selectively applied to printed circuit boards (PCBs) to protect sensitive components from environmental conditions. It’s especially important in high-reliability sectors such as automotive, aerospace, consumer electronics, and telecommunications. An improperly applied conformal coat can lead to circuit failures, corrosion, or short circuits.

Manual methods of inspecting conformal coating are time-consuming and prone to human error. This is where a Conformal Coating AOI system steps in to safeguard quality and streamline production.

What Is a Conformal Coating AOI System?

A Conformal Coating AOI system is a specialized optical inspection solution designed to identify coating coverage, thickness, and potential defects such as bubbles, cracks, or missing areas. Equipped with sophisticated lighting, imaging, and software algorithms, these systems offer consistent inspection results across high-speed production lines.

Unlike traditional manual inspections that rely on UV light and human judgment, AOI systems use cameras and UV-sensitive sensors to ensure a meticulous and reliable review of the coating materials. They can be integrated in-line for real-time inspections or used offline for spot checks and validation.

Top Reasons Why a Conformal Coating AOI System Is Essential

1. Improved Defect Detection

Manual inspection methods are inherently subjective and inconsistent. A Conformal Coating AOI system removes human bias by using calibrated optics and intelligent algorithms to consistently catch a wide range of defects, including:

- Insufficient or excessive coating

- Delamination or bubbling

- Cracks and voids

- Non-uniform thickness

- Foreign materials trapped in the coating

As a result, manufacturers can dramatically increase first-pass yield while boosting production quality.

2. Enhanced Throughput

Time-consuming manual inspections often become bottlenecks in the production process. AOI systems can inspect boards in seconds rather than minutes, allowing much faster throughput without compromising inspection accuracy. In fact, modern AOI systems can inspect hundreds of PCBs per hour, making them ideal for high-volume production lines.

3. Consistent Reporting and Traceability

A key advantage of automated systems is data logging and traceability. All inspection results can be digitally stored and analyzed, facilitating process improvement initiatives and compliance documentation. This is especially critical in regulated industries like medical devices and aerospace, where traceability is mandatory.

4. Cost Efficiency Over Time

Although an initial investment is required, a Conformal Coating AOI system quickly pays for itself by reducing labor costs, rework, and field failures. Manufacturing defects caught early in the process are significantly cheaper to rectify than those found during functional testing or by the end-user.

5. Seamless Integration with Existing Equipment

Modern Conformal Coating AOI systems are designed for easy integration into existing production lines. Whether used inline immediately after the coating process or as part of the final inspection stage, these systems offer versatile installation options and are compatible with most conveyor systems and programmable logic controllers (PLCs).

Industries Reaping the Benefits of AOI in Conformal Coating

Various sectors rely heavily on conformal coatings—and each has unique reasons to implement AOI within their production lines:

- Automotive: Requires long-life electronics exposed to fluctuating temperatures and humidity

- Aerospace: Demands unmatched reliability, where failure risk translates to catastrophic results

- Medical Devices: Compliance standards require precise inspection and traceability

- Consumer Electronics: High throughput with low error tolerance is essential for brand reputation

Quality Assurance and Standard Compliance

In many industries, adherence to standards such as IPC-CC-830 and MIL-I-46058 is necessary. These standards specify coating performance and inspection guidelines. A Conformal Coating AOI system aids in compliance by generating inspection reports that align with industry benchmarks, making audits more manageable and reducing risk exposure.

Future-Proofing the Manufacturing Process

As electronics become more complex and customer expectations continue to rise, traditional quality control methods simply won’t cut it. Investing in an AOI system not only ensures current standards are met but also prepares manufacturers for future demands in automation and Industry 4.0 integration. With features like machine learning, remote monitoring, and predictive analytics, AOI systems will only get smarter—and more essential.

Conclusion

The application of conformal coating is a crucial step in electronics manufacturing, and ensuring its quality through optical inspection is no longer optional—it’s essential. A Conformal Coating AOI System offers a practical and scalable solution for consistent quality assurance, increased productivity, and cost savings. As customer expectations rise and regulatory requirements become more stringent, there has never been a better time to integrate AOI into your production line.

FAQs about Conformal Coating AOI Systems

-

Q: Can AOI systems detect all types of conformal coating defects?

A: While AOI systems are highly effective, their ability to detect defects depends on the type of coating used, the thickness, and the system’s configuration. Most systems can detect a wide range of common defects such as bubbles, missing areas, delamination, and overspray. -

Q: Is it difficult to integrate an AOI system into an existing production line?

A: No, most modern AOI systems are designed for quick and seamless integration with current manufacturing setups. They can be installed inline or offline depending on space and process requirements. -

Q: How does AOI improve ROI (Return on Investment)?

A: AOI systems minimize labor costs, reduce product rework and recalls, and help catch defects early in the process. All these benefits translate into faster ROI, typically within months of deployment. -

Q: Do AOI systems support multiple coating materials?

A: Yes, most AOI systems are flexible enough to inspect various types of coatings, including acrylic, urethane, epoxy, and silicone. Configuration may be needed to optimize settings for different materials. -

Q: What kind of maintenance do AOI systems require?

A: AOI systems are relatively low maintenance but should undergo regular calibration, lens cleaning, and software updates to ensure consistent performance and accuracy.