In the fast-paced world of industrial automation and robotics, the term teach pendant often comes up in discussions about programming and operating robots. Whether you’re a seasoned automation engineer or a curious beginner, understanding what a teach pendant is and how it plays a central role in robotic innovation is important.

TL;DR

A teach pendant is a handheld device used to program and control industrial robots. It allows operators to input commands, adjust movements, and monitor robot operations directly and efficiently. These tools are essential in manufacturing and automation, facilitating both simple tasks and complex robotic choreography. With evolving technology, teach pendants now come in both traditional wired forms and modern touchscreen interfaces.

What Exactly Is a Teach Pendant?

A teach pendant is a handheld control device used to interact directly with an industrial robot. It serves as an interface between the operator and the robotic system, allowing the user to control, monitor, and teach the robot specific actions or tasks. The term “teach” comes from the ability of this device to instruct a robot on how to complete a sequence of operations, either by manual intervention or by guiding it through a path.

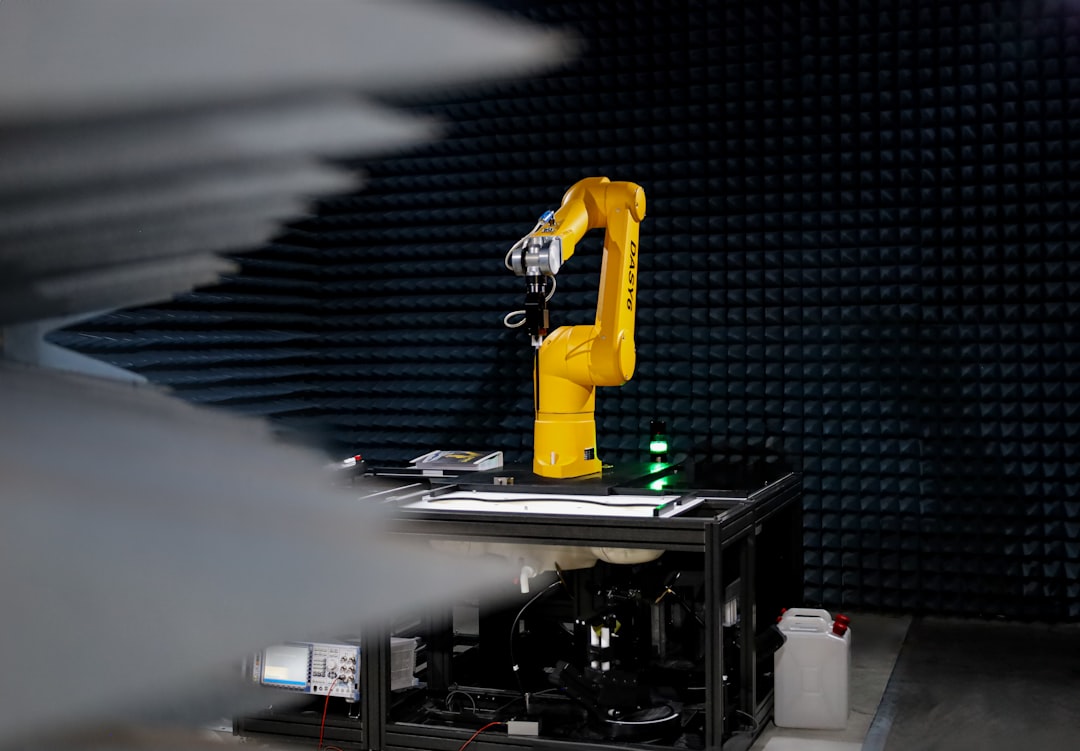

Originally, teach pendants were bulky, wired devices with buttons and joysticks, but modern pendant designs are now sleeker and often include full-color touchscreens, intuitive interfaces, and wireless connectivity. They are commonly found in settings where robots are used for welding, painting, assembly, packaging, and more.

Key Functions of a Teach Pendant

While teach pendants can vary depending on manufacturer and robot model, their core functions are quite similar. Here are several key capabilities:

- Manual Control: Operators can move the robot arm in various directions and orientations, often using joystick-style controls or touchscreen arrows.

- Programming: Users can program specific movements or sequences, saving these instructions in the robot’s memory.

- Jogging: The pendant lets the robot be incrementally moved, either continuously or by prescribed steps.

- Monitoring: It displays real-time feedback about the robot’s status, position, and condition.

- Error Handling: Operators can diagnose and reset faults directly from the pendant interface.

- Safety Controls: Emergency stop buttons and dead-man switches ensure safe operation.

Types of Teach Pendants

Teach pendants come in various styles and capabilities, depending largely on the complexity of the robot and the application environment. Here are the main types:

- Traditional Wired Pendants: These are tethered to the robot and feature physical buttons and joysticks. They are highly reliable and commonly used in legacy systems.

- Touchscreen Pendants: Modern systems often favor touchscreen interfaces resembling tablets, with easy-to-navigate menus and visual tools for more complex instruction sets.

- Wireless Pendants: Some advanced systems now offer wireless connectivity, offering increased flexibility and ergonomics, though with slightly higher security considerations.

Choosing the right type depends on the system’s requirements, the operator’s preference, and the specific tasks the robot will perform.

Teach Pendants vs. Offline Programming

As robot systems have evolved, so too have the programming methods. Teach pendants represent one way of programming, where the human operator directly manipulates or programs the robot physically at the machine. But how does this compare with offline programming, which allows code to be written and simulated on a computer before deployment?

- Ease of Use: Teach pendants are more hands-on and simpler to use for real-time adjustments or fine-tuning.

- Accuracy: Offline programming allows for more precise simulations and planning, ideal for complex workflows.

- Downtime: Offline methods minimize robot downtime because programming doesn’t interfere with actual production runs.

- Training: Teach pendants are excellent tools for learning and training, especially for those new to robotics.

In many industrial environments, a combination of both approaches yields the best performance and flexibility.

Common Applications in Industry

Teach pendants are used in an impressive variety of industries and applications. Here are a few examples:

- Automotive Manufacturing: Robotic arms used in car assembly lines are often programmed and adjusted via teach pendants.

- Welding and Painting: Precision-style jobs benefit from real-time adjustments that teach pendants can provide.

- Food and Beverage Handling: Teaching robots how to delicately pick and package items is often done through pendants.

- Electronics Assembly: Small and sensitive components require exact placement, which the manual control aspects of pendants make possible.

Advantages of Using a Teach Pendant

There’s a reason teach pendants remain a staple in industrial robotics. Here are some of their most valuable benefits:

- User-Friendly: Operators can interact directly with the robot, making learning and adjustments straightforward.

- Immediate Feedback: Engineers and technicians get real-time visual confirmation of changes and operations.

- Portable and Flexible: Teach pendants can be easily moved around the work cell, allowing for multiple viewpoints and tight-space operation.

- Safe Learning Environment: With built-in safety features like emergency stop and enabling switches, teach pendants offer a secure platform for controlling robots.

Challenges and Limitations

Despite their advantages, teach pendants aren’t without limitations:

- Learning Curve: While more intuitive than some software systems, new users may still need extensive training.

- Production Downtime: Real-time teaching generally requires the robot to stop its operations, leading to decreased productivity during programming.

- Ergonomics: Extended use can lead to operator fatigue, especially with older, heavier units.

Manufacturers are addressing these limitations by designing lighter, more ergonomic devices and integrating voice commands and augmented reality for future applications.

The Future of Teach Pendants

As automation advances, so do the capabilities of teach pendants. Here are a few innovations on the horizon:

- Voice-Control Integration: Hands-free operation may become the norm, allowing faster task management.

- Augmented and Virtual Reality: Wearing AR or VR headsets while teaching a robot may enhance visibility and precision in complex environments.

- Cloud Connectivity: Wireless data sync with servers allows for effortless updates, diagnostics, and remote teaching.

Teach pendants are also becoming more collaborative, designed to work with operators in shared spaces alongside collaborative robots, or “cobots.” These new pendants often include gesture recognition, intuitive UIs, and seamless integration with mobile devices.

Conclusion

The teach pendant may look like a simple device at first glance, but it plays a crucial role in modern robotics. It gives human operators fine control over machines that execute millions of precise, repetitive tasks in every industry imaginable. As technology evolves, so too will these handheld interfaces—becoming smarter, safer, and even more user-friendly.

Whether you’re programming a high-speed robotic arm on a car assembly line or teaching a collaborative robot to serve coffee, the teach pendant is your gateway into the robotic world. It’s where human creativity meets machine precision.